The Hidden Cost of Poor Cold Storage Doors (and How to Fix It)

- Therm-L-Tec Systems LLC

- Sep 3, 2025

- 2 min read

Think of your cold storage doors as the “front lines” of your operation. Every time they open, warm air sneaks in, cold air rushes out, and your refrigeration system works harder. Over time, this invisible problem turns into very visible costs: higher utility bills, equipment strain, spoiled inventory, and frustrated employees.

The good news? The right door technology can flip the script—turning a constant energy drain into one of the smartest efficiency upgrades your business can make.

1. The Problem: Energy Leaks You Can’t See

Every minute a poorly sealed or slow-moving door is open, refrigerated air escapes.

Did you know?

A 10’ x 10’ freezer door left open for just 1 minute can let in enough warm, humid air to cause excessive frost accumulation every day on your evaporator coils.

Facilities with outdated doors often spend 20–30% more on energy costs annually compared to those with modern high-performance solutions.

2. The Impact on Your Operation

Rising Energy Bills – Your compressors run harder and longer to compensate.

Product Loss – Inconsistent temps = spoilage and safety risks.

Employee Safety – Frost buildup leads to slippery floors and damaged equipment.

Downtime – Manual repairs and unscheduled maintenance cost more than planned upgrades.

3. The Solution: Modern Cold Storage Door Technology

High-performance and properly insulated doors are designed to solve these hidden costs.

Tighter Seals prevent costly air infiltration.

High-Speed Operation reduces open time by up to 80%.

Advanced Insulation keeps cold air where it belongs.

Automated Systems improve traffic flow and reduce operator error.

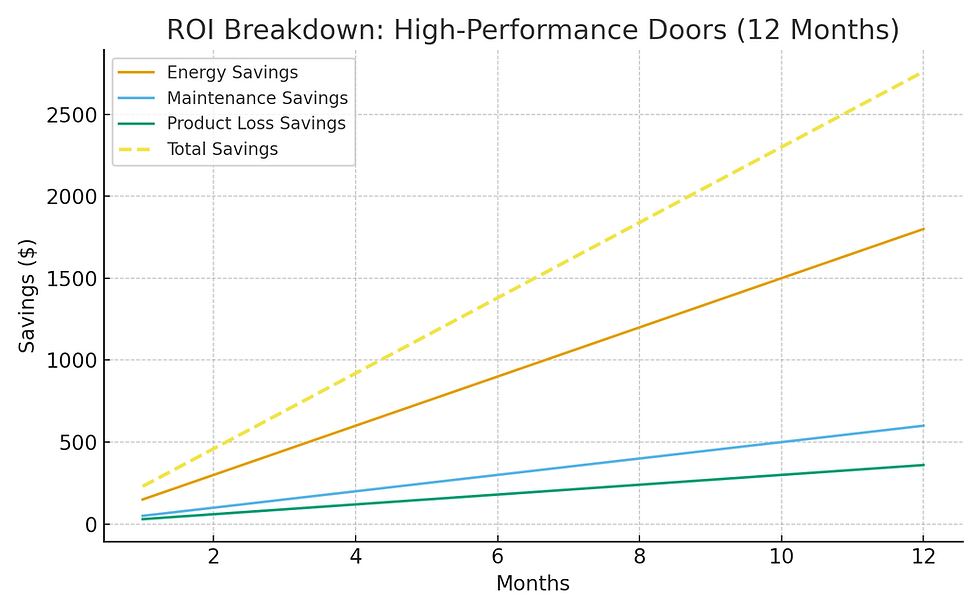

4. Case Study Snapshot: ROI in Real Numbers

Here’s what a typical facility might save after upgrading just two high-traffic freezer doors:

Category | Before Upgrade | After Upgrade | Savings |

Annual Energy Cost | $125,000 | $100,000 | $25,000 |

Maintenance & Downtime | $15,000 | $8,000 | $7,000 |

Product Loss | $10,000 | $2,000 | $8,000 |

Total Annual Savings | – | – | $40,000 |

That’s a 32% reduction in costs—meaning the doors paid for themselves in under 12 months.

5. How to Know If It’s Time to Upgrade

Are your energy bills climbing even without more production?

Do you see frequent frost or ice buildup near your doors?

Are your employees waiting on slow doors, or reporting safety concerns?

Has it been more than 10 years since your last upgrade?

If you answered “yes” to any of the above, your doors are costing you money.

Every cold storage facility has a silent cost center hiding in plain sight: its doors. By investing in high-performance, insulated, and properly maintained doors, you’re not just protecting your products—you’re protecting your bottom line.

At Therm-L-Tec, we specialize in doors that seal, cycle, and save. Let’s talk about how much your facility could save this year.

Call us at (913) 728-2662, or email us your questions at techsupport@thermltec.com to keep your operation running at peak performance.

Comments